---- Hardworking Indian buyer, best quality and product for client

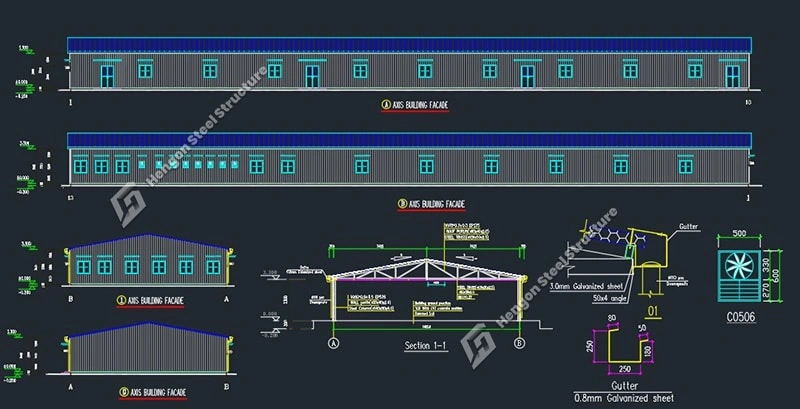

Hot dip galvanized square prefabricated steel structure

In one year, this client ordered 2 office buildings, 1 warehouse, 2 supermarkets, 10 restrooms, and 12 staff dormitories with us. These orders were placed in three batches, all using hot galvanized square tube prefabricated steel structures. This article focuses on one of the office buildings.

| Nigeria prefab structure office ---- Hardworking Indian buyer, best quality and product for clientcrane | |||||

| Country | Nigeria | Year | 2018 | ||

| Project Information | |||||

| Project | Prefabricated steel structures office | Dimension | 65*15*3.3m | ||

| Material | Q235B Hot galvanized square tube,160g | Purline | Square tube 80x40x2.0, | ||

| Roof | EPS sandwich panel V970 0.7mm+75mm 18kg+0.37mm) | Wall | EPS sandwich panel V950 0.5mm+75mm 18kg+0.5mm | Window | Alluminum alloy sliding window, 1mm frame+0.5mm tempered glass 1.2mx1.2mx26;Louver window:0.5mx0.6mx8 |

| Door | Steel Security door | Roof Drainage | 0.8mm galvanized gutter+110 pvc downspout | Containers | 5x40HQ |

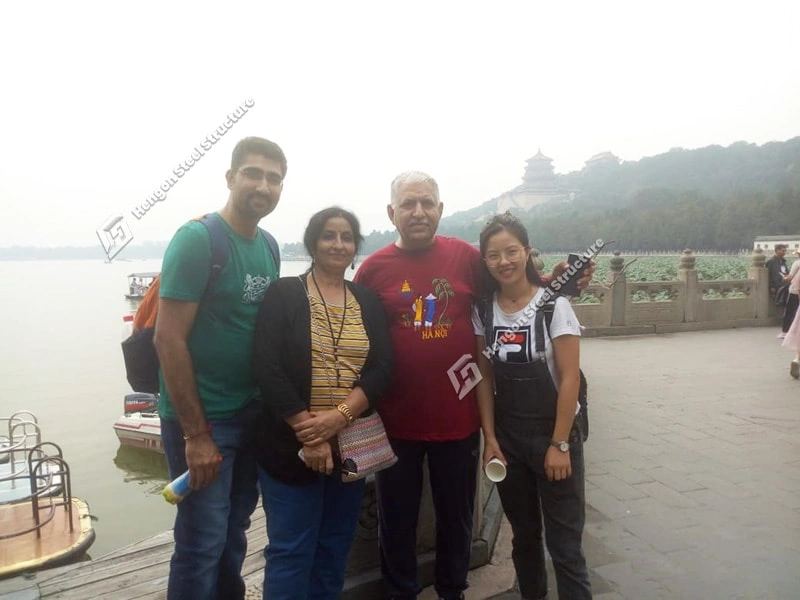

This client was an engineer and values design and quality as much as price. Before confirming this project, he spent a week at our factory to finalize the design. After our engineer team made the adjustments, he reviewed and proposed optimizations until it was fully satisfied. We welcome such dedicated clients to visit our factory for project discussions, as thorough preparation is key to ensuring smooth project execution.

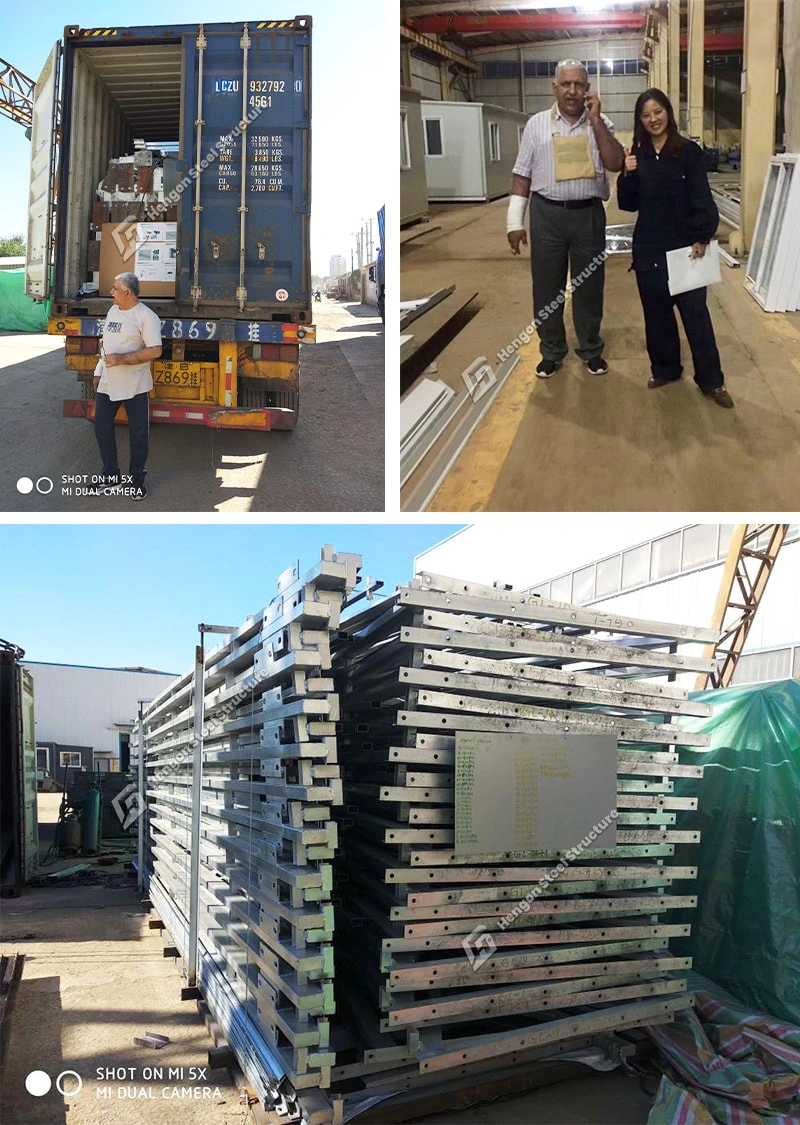

During production, this client visited our factory twice to follow up on progress and randomly inspect product quality. He checked items like steel structure component dimensions, thickness, zinc coating. Sandwich panel`s thickness, and density, all based on the requirements in the quotation. This client satisfied with our quality, and gave us a thumbs-up, saying they could confidently report to their direct client.

He is Indian, with a trading company registered in Dubai. He mainly helps African clients source suppliers globally and ensures project implementation.

During shipping, this client stayed at our workshop to supervise the loading process, even staying until 11 p.m. at night. Who is over 60 years old, his dedication deeply impressed us, as did his professionalism. It’s no wonder his direct clients trust him and entrust him with such a major project’s procurement work.

For this project, we assigned an engineer to guide installation, our engineer spent 52 days on-site in Nigeria. Our engineer assignment is a paid service, and the visa, round-trip airfare and local accommodation are also charged. However, ensuring the project is completed on schedule helps avoid greater losses.